UV filters are the functional component of sunscreens while the formulation is the “art.” The general goal in formulating modern sunscreens is to design the best product that meets the desired UV efficacy targets of SPF, UVA/broad spectrum protection, and substantivity,

i. e., water/wear resistance. Typically, the best product is the one that most effectively manages factors such as cost, skin compatibility, and aesthetics/skin feel (46).

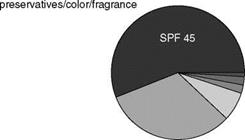

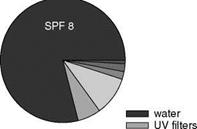

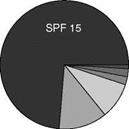

From an ingredient standpoint, most sunscreen products are typically very similar to conventional lotions or creams, with the key difference being the addition of 4% to 40% sunscreen actives (Fig. 1). From a formulation perspective, the current list of UV filters (Table 2) can be categorized into one of four groups based on the physical properties of the active:

• Polar oils, e. g., octinoxate, octisalate, homosalate, and octocrylene

• Oil soluble crystalline solids, e. g., avobenzone, and the benzophenones

• Water soluble salts, e. g., ensulizole

• Insoluble powders/particulates, e. g., zinc oxide and titanium dioxide

|

Importantly, given the concentration of UV filters used in sunscreen products, i. e., up to 40% for high SPF products, and their physical properties, by far the greatest factor involved in managing cost, skin compatibility, and aesthetics/skin feel in formulating new sunscreen products is the selection and combination of these sunscreen actives.

Cost

Current sunscreen actives are expensive relative to the key ingredients utilized in most lotion and cream vehicles, typically ranging from $10 to $100 per kilogram. Thus, the higher the level of sunscreen actives in a formulation, the greater the formula cost, and hence the more marketers charge for the product. In turn, and perhaps as a direct consequence, one might expect that the more expensive the sunscreen product the more sparingly, i. e., lower dose and reduced frequency, it will be used by consumers (47).